Applications include in printed circuit board (PCB), Flexible board (FPC), IC substrate and packaging, High Density Interconnects board (HDI), ceramic substrate ... Full automation equipment with whole plant logistics design, and intelligent automation integration service.

This unit is specialized in designing fully customized machines that adapt to the client's specifications. Their applications include laser technology equipment, TFT-LCD flat panel screens, LEDs, Touch Panels, LGP... Full automation with whole plant logistics, information integration design, and service.

Application in wafer, cell and module manufacturing machines; including inspection system and offering turnkey solution as well.

Applications in Automated Guided Vehicle(AGV), Rail Guided Vehicle(RGV), Warehouse Integration System(WIS), intelligent control system, firmware design and control, logistics communication control, visual system design, and other industrial automation system integration services.

SB-101 30 pcs. Flip Cooler

PCB automation suitable for all processes that need cooling, staying, accumulating, flipping or inspecting.

PCB automation suitable for all processes that need cooling, staying, accumulating, flipping or inspecting.

SB-300 Double Conveyor Flipper

PCB automation suitable for any process, like belt sanding, that needs to turn over rigid boards.

PCB automation suitable for any process that needs to turn over rigid boards, like belt sanding.

SB-308A Flip Machine

PCB automation suitable for rotating rigid panels between processes.

PCB automation suitable for rotating panels between processes.

SB-503 Buffer Machine

PCB automation suitable for buffering between any kind of PCB processes.

PCB automation suitable for buffering between any kind of PCB processes.

SC-101 Positioning Machine

PCB automation suitable for changing the alignment of rigid panels between processes.

PCB automation suitable for changing the alignment of rigid panels between processes.

SLR/SUR-246 Automatic Loader / Unloader

PCB automation suitable for loading and unloading of various processes without soldermask.

PCB automation suitable for loading and unloading of various processes without soldermask.

SLR/SUR-246P Automatic Loader / Unloader

PCB automation suitable for loading and unloading of various processes without soldermask, to or from boxes or cassettes at different preset angles and using interleaf.

PCB automation suitable for loading and unloading of various processes without soldermask, to or from boxes or cassettes at different preset angles.

ST-103 4-way Panel Diverter

PCB automation suitable for diverting rigid boards between different processes.

PCB automation suitable for diverting rigid boards between different processes.

ST-201 Panel Rotator

PCB automation suitable for rotating rigid boards between processes

PCB automation suitable for rotating rigid boards between processes

SLR/SUR-628C 6-axis Handler Robot

PCB automation suitable for loading / unloading panels from individual trays.

PCB automation suitable for loading / unloading panels from individual trays.

SLR-608 Loader/Unloader for AOI/DI processes

PCB automation suitable for handling panels for any AOI/DI processes that need panel flipping.

PCB automation suitable for handling panels for any AOI/DI processes that need panel flipping.

SUR-128 Double tray / magazine unloader

PCB automation suitable for unloading panels to either tray or L-rack.

PCB automation suitable for unloading panels to either tray or L-rack.

SLF/SUF-200A Roll-to-roll

FPC automation suitable for handling either single or double 250mm rolls, or single 500mm rolls for wet process, in continuous operation.

PCB automation suitable for handling either single or double 250mm rolls, or single 500mm rolls for wet process, in continuous operation.

SLF/SUF-230 DES wet process

FPC Automation suitable for either single 500mm or 250mm wide material, in continuous roll-to-roll production.

FPC Automation suitable for either single 500mm or 250mm wide material, in continuous roll-to-roll production.

SLF/SUF-300D/300E Roll-to-roll handling system

FPC automation suitable for handling single (250mm) or double (500 mm) width material for wet process, in roll-to-roll continuous operation.

PCB automation suitable for handling single (250mm) or double (500 mm) width material for wet process, in roll-to-roll continuous operation.

SLF/SUF-233 Roll-to-roll handling system

FPC automation suitable for handling single (250mm) or double (500mm) material for wet process in continuous operation.

PCB automation suitable for handling single (250mm) or double roll (500mm) material for wet process in continuous operation.

SLF/SUF-310A Roll-to-roll handling system

FPC Automation suitable for handling single 250mm or 500mm material for AOI process.

FPC Automation suitable for handling single 250mm or 500mm material rolls for AOI process.

SLF/SUF-350C Roll-to-roll handling system

FPC automation suitable for handling single (250mm) or double (500mm) VRS material in roll-to-roll continuous operation.

FPC automation suitable for handling single (250mm) or double (500mm) VRS material in roll-to-roll continuous operation.

SVF-200/200A for Yamaha punching system

FPC automation suitable for YAMAHA FC602L2/S2 sheet process.

FPC automation suitable for YAMAHA FC602L2/S2 sheet process.

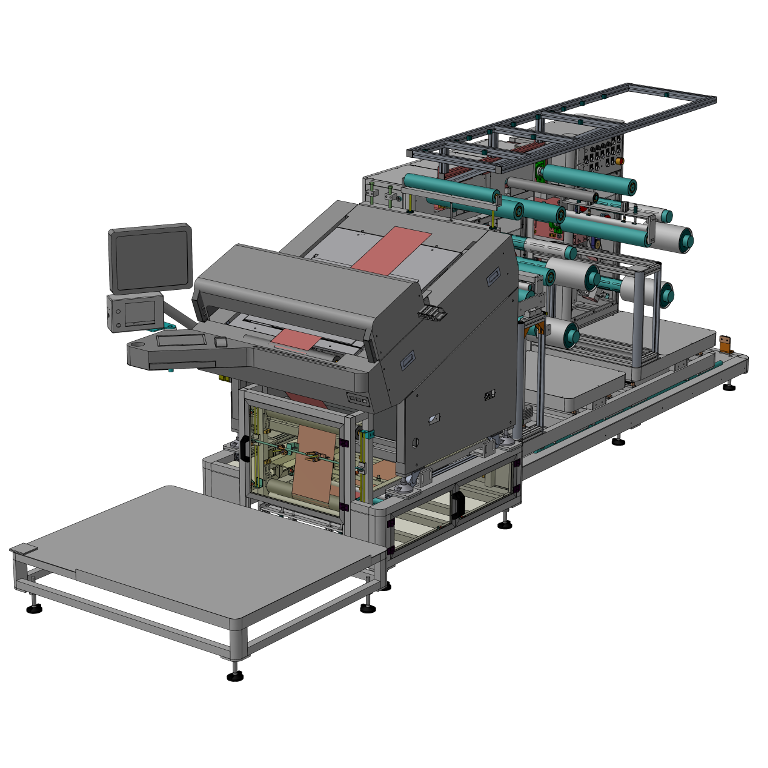

FP-100 Dense Packer System

Loader/Unloader system suitable for packing or unpacking TFT substrates into or from transport boxes.

Loader/Unloader system suitable for packing or unpacking TFT substrates into or from transport boxes.

FP-101 Dense Packer System

Loader/Unloader system suitable for packing or unpacking TFT substrates into or from transport boxes.

Loader/Unloader system suitable for packing or unpacking TFT substrates into or from transport boxes.

FL/FU-100 Loader/Unloader system

Loader/Unloader system suitable for loading and unloading TFT substrates into and from the manufacturing line.

Loader/Unloader system suitable for loading and unloading TFT substrates into and from the manufacturing line.

FP-200 Cell CF Packer/Unpacker System

Packing/Unpacking system suitable for packing or unpacking TFT substrates into or from transport cassettes.

Loader/Unloader system suitable for packing or unpacking TFT substrates into or from transport cassettes.

FP-106 Dense Packer System

Loader/Unloader system suitable for packing or unpacking TFT substrates into or from transport boxes.

Loader/Unloader system suitable for packing or unpacking TFT substrates into or from transport boxes.

FV-102 Loader/Unloader system

Suitable to inspect TFT substrates visually from different angles to identify defects and scratches.

Automation system suitable to inspect TFT substrates visually from different angles to identify defects and scratches.

FLS-100 Laser short ring cut

Suitable to interrupt electrical circuits on TFT substrates.

Automation Laser system suitable to interrupt electrical circuits on TFT substrates.

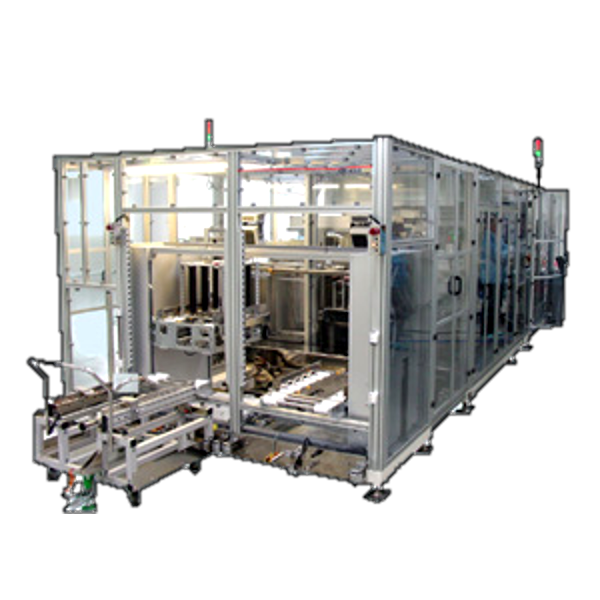

Wafer Carrier Stocker

For the different storage needs of cleanroom space planning, SAA can provide standard stocker as well as ZIP stocker for storing carriers, including 300mm FOUP and 200mm SMIF Pods.

For the different storage needs of cleanroom space planning, SAA can provide standard stocker as well as ZIP stocker for storing carriers, including 300mm FOUP and 200mm SMIF Pods.

Reticle Carrier Stocker

For the different storage needs of cleanroom lithography area space planning and process requirement, SAA can provide standard stocker as well as ZIP stocker for storing carriers, reticle pod, reticle box, and EUV pod.

For the different storage needs of cleanroom lithography area space planning and process requirement, SAA can provide standard stocker as well as ZIP stocker for storing carriers, reticle pod, reticle box, and EUV pod.

Backend Carrier Stocker

For cleanroom space planning in the IC backend packaging and testing, SAA can provide standard stocker as well as ZIP stocker for storing carriers, including Tray Cassettes and Magazines.

For cleanroom space planning in the IC backend packaging and testing, SAA can provide standard stocker as well as ZIP stocker for storing carriers, including Tray Cassettes and Magazines.

Montrac® RGV

This Rail-Guided Vehicle is suitable to link different processing stations by mens of a light and compact monorail system and fast, efficient, self-propelled shuttles.

This Rail-Guided Vehicle is suitable to link different processing stations by mens of a light and compact monorail system and fast, efficient, self-propelled shuttles.

AGV L1200S

Automatic Guided Vehicle system suitable for transporting a load up to 1.2 tons in any operational environment, also in combination with traffic of people and industrial trucks.

Automatic Guided Vehicle system suitable for transporting a load up to 1.2 tons in any operational environment, also in combination with traffic of people and industrial trucks.

Mobile Robot (MR)

The mobile robot comprises an AGV and a six-axis robotic arm. With a reliable safety design, the AGV can work with personnel or perform tasks independently.

The mobile robot comprises an AGV and a six-axis robotic arm. With a reliable safety design, the AGV can work with personnel or perform tasks independently.

Overhead Conveyor (OHCV)

The OHCV offers high transfer speeds and a zero footprint, effectively connecting OHT and other machines, such as cross-floor lifts.

The OHCV offers high transfer speeds and a zero footprint, effectively connecting OHT and other machines, such as cross-floor lifts.

RGV Material Handling System

RGV AMHS makes transporting material with various automated equipment possible.

AGV Material Handling System

A variety of AGVs such as latent lift AGVs and forklifts etc., can be integrated with AGV AMHS to benefit your intelligent factory.

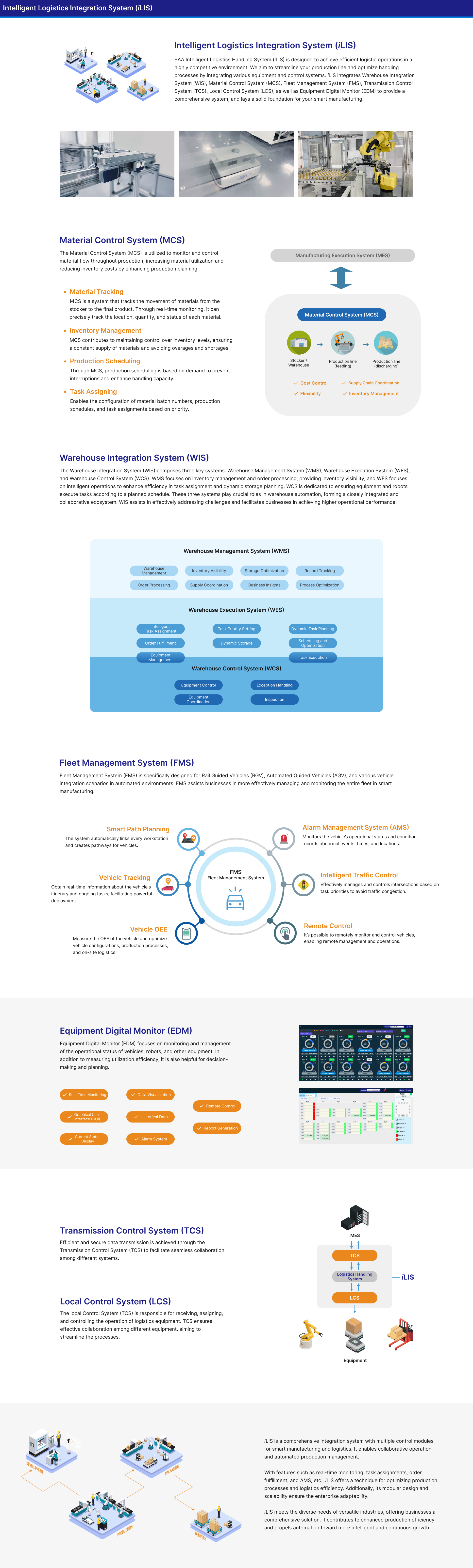

iLIS

Highly integrates multiple systems and functions of smart logistics to achieve automatically managed production.

Material Control System

Optimizes and controls the flow of materials in manufacturing processes, aiming to enhance material utilization.

Warehouse Integration System

Focus on optimizing and managing inventory, order processing, and operational workflows.

Fleet Manager System

Effectively coordinating the operation of AGVs, and RGVs also can enhance efficiency and safety.

Equipment Digital Monitor

Real-time monitoring of the equipment status, able to assessment of equipment utilization efficiency.